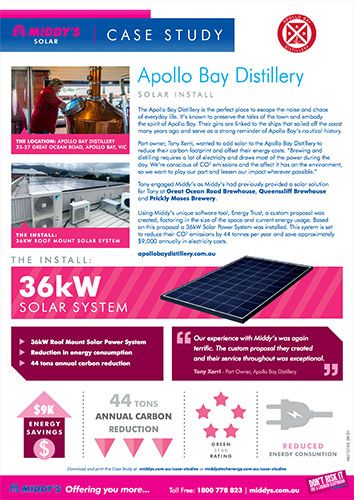

Apollo Bay Distillery Solar Install

The Apollo Bay Distillery is the perfect place to escape the noise and chaos of everyday life. It’s known to preserve the tales of the town and embody the spirit of Apollo Bay. Their gins are linked to the ships that sailed off the coast many years ago and serve as a strong reminder of Apollo Bay’s nautical history.

TAFE NSW Training Centre Septic Control Panel Install

Troy Crawford (Middy’s Industrial & Automation BDM Central & Northern Victoria, Riverina & ACT) was approached by R&R Electrical to discuss a potential upgrade to the 4-pit septic system currently in service at the TAFE NSW - National Environment Centre. The unique training facility is located in Thurgoona, 10km from Albury NSW. It is a specialist training centre in Civil Construction and is used to provide theory and practical work for students. Talks developed where the existing system had never been fully functional and needed a full fit out to get it up to standard.

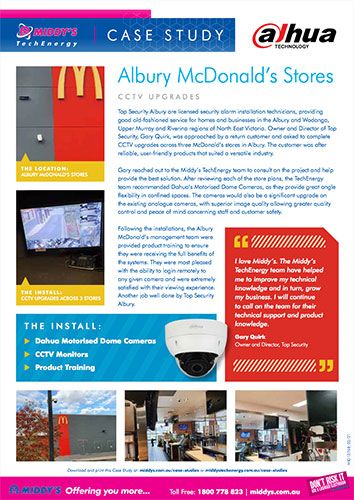

Albury McDonald’s Stores CCTV Upgrades

Top Security Albury are licensed security alarm installation technicians, providing good old-fashioned service for homes and businesses in the Albury and Wodonga, Upper Murray and Riverina regions of North East Victoria. Owner and Director of Top Security, Gary Quirk, was approached by a return customer and asked to complete CCTV upgrades across three McDonald’s stores in Albury. The customer was after reliable, user-friendly products that suited a versatile industry.

Billy & Nicole Slater Home Automation & Solar Install Case Study

Former professional rugby league footballer, Billy Slater and his wife Nicole chose Middy's to help them create an eco friendly, smart home with up to date modern technology after a recommendation from their trusted electrician Mitch from Hayes Power. Mitch works on a lot of high-end, modern homes and uses Middy's whenever he can because of their great products and service.

Strathmore Hotel Automation Install Case Study

Middy’s TechEnergy and Smart Tech Electrical combined to give the 165 year old Strathmore Hotel a significant technology upgrade. Staff are now able to control the many staging areas of the venue at their fingertips with a fully integrated C-Bus automation system.

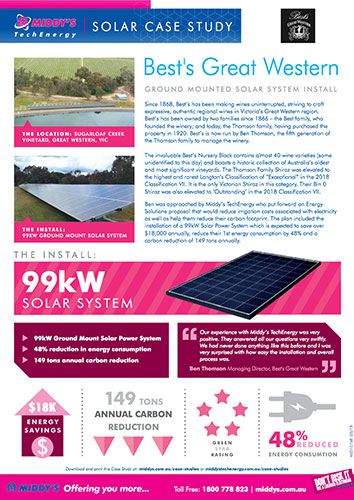

Best's Great Western Solar Install Case Study

Since 1868, Best’s has been making wines uninterrupted, striving to craft expressive, authentic regional wines in Victoria’s Great Western region. Best’s has been owned by two families since 1866 – the Best family, who founded the winery; and today, the Thomson family, having purchased the property in 1920. Best’s is now run by Ben Thomson, the fifth generation of the Thomson family to manage the winery.

Fernlea Park Farm Solar Install Case Study

Eddie Kenna is a South West Victorian dairy farmer and owner of Fernlea Park Farm at The Sisters. For many years Mr Kenna has looked for opportunities to attain a competitive advantage in the market as well as opportunities to reduce operational cost.

Billy Slater Home Automation & Solar Installation (2:19)

Middy’s help Billy Slater and his wife Nicole achieve their goal of having an eco friendly smart home with all the latest technologies. The result being a high end, modern home with reduced power bills and remote access via wifi from anywhere in the world.

Capitol Cinema Solar Install Case Study

TechEnergy Representative, Leigh Stacey, approached Capitol Cinema to see whether there was any interest in discussing solar, as TechEnergy had recently completed an installation on the Warrnambool Hotel. Talks developed and it became evident that Capitol Cinema would be ideally suited for a solar panel installation, which would substantially reduce their grid usage and ultimately decrease their power bill

Fibaro Lifestyle Control Case Study

Middy's customer, Scott Greatrex (Director, GEN2 Power) owns a remote rural property, one hour from Adelaide. Scott was looking to automate his two-storey home. He wanted to be able to remotely turn on air conditioning prior to arrival and automate the home to meet his family's expectations and to match their lifestyle. The Middy’s TechEnergy team worked with Scott to install a FIBARO Home Automation System. This included Air Conditioning control, SONOS sound system, garage door opener, ceiling fans, lighting and access control.